Our partner network

Plasmatreat has purposefully built up an innovative network of entrepreneurs, educational and research institutions, funding organizations, interest groups and associations in recent years. They all have something in common: the pursuit of new, good ideas for surface treatment. Our technology and innovation experts know their way around the various fields and use the combination of skills to bring new ideas to life again and again.

At our events in the Plasmatreat Academy, we can draw on our partner network and invite them, for example, to joint networking events. Attending one of our events is definitely worthwhile, whether it is to gather ideas, to exchange ideas among like-minded people or to find support as well as a competent partner at your side for the current challenges or next innovation projects.

Successful industry partnerships

Working togehter for success with our partners in industry. Using our plasma technology in industry and offering the best solution is one of our guiding principles. To achieve this, we work hand in hand with our customers.

Our most inspiring R&D projects

Working together for success with our partners in science and conduct research with institutes and universities.

CREPIM-Innovative

The French CREPIM Institute focuses on researching fire-retardant materials in all types of industries that are subject to fire protection regulations. Their laboratory uses PlasmaPlus® polymerization to improve behavior in fire of very different substrates.

Federal Ministry of Education and Research

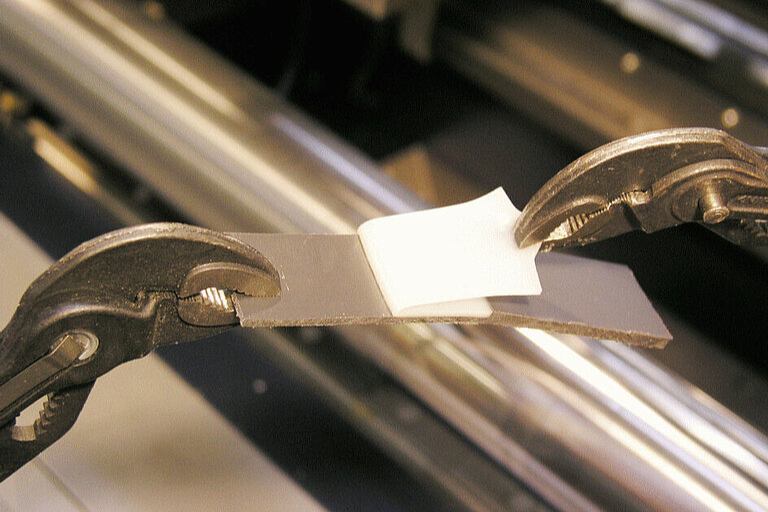

Project EFFICIAT: Conventional sheet metal construction in automobile manufacturing is being replaced by new, lightweight techniques. With plasma coating, new composite materials can be reliably bonded – even without solvent-based primers.

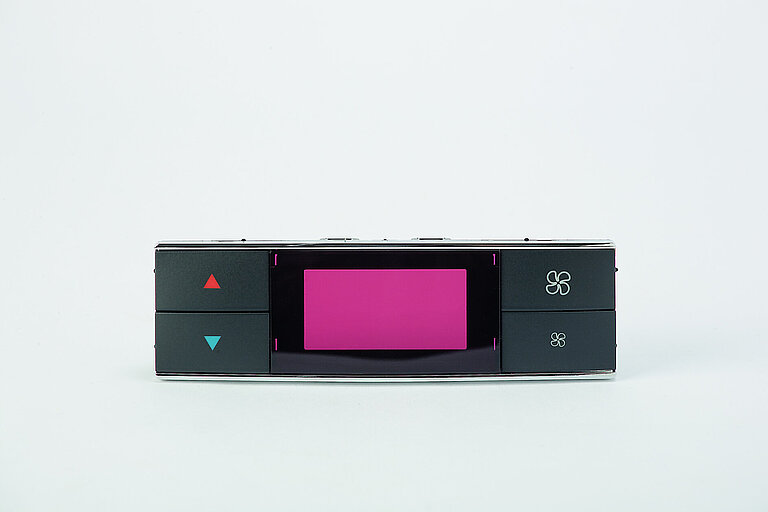

Project PROTECT-SELECT: Thin, transparent insulating plasma polymer coatings that protect against aging can be deposited successfully with PlasmaPlus® to protect electronic components in selected areas.

Fraunhofer IFAM

Since the mid-1990s, Plasmatreat has had a strategic partnership with Fraunhofer IFAM, Europe’s largest independent research institution for industrial bonding technology, which has resulted in many jointly-developed projects.

Freudenberg Forschungsinstitute KG

Freudenberg Forschungsdienste KG rates plasma technology as the technology of the future for surface modifications due to its environmentally friendly and resource-efficient nature.

Plasma Nano-Tech (Environment Park S.p.A.)

Working closely with Plasmatreat, plasma researchers at Environment Park, the Italian Science and Technology Center, have succeeded in using Openair-Plasma® and PlasmaPlus® technologies to develop and patent a groundbreaking process for the ski industry.

Plastics technology Paderborn

The increasing demands on the look, feel and function of plastic components require further development of multi-component injection moulding. The compatibility of different components is to be increased and the process efficiency optimised while at the same time conserving resources in production.

University of Erlangen-Nürnberg

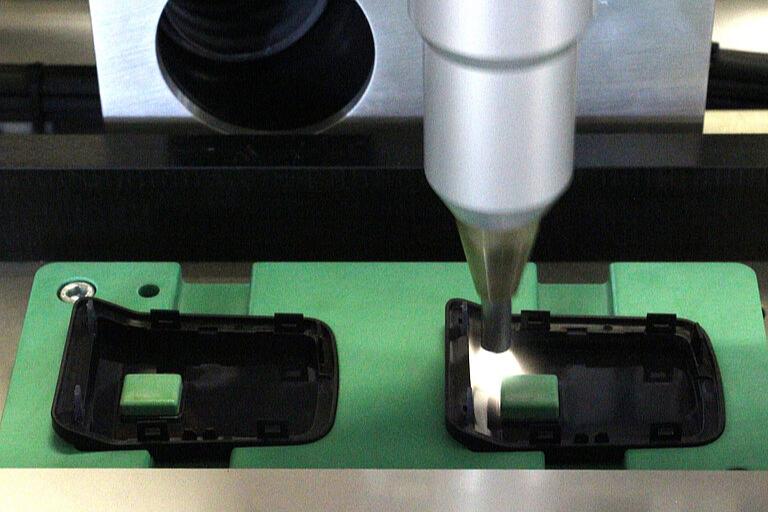

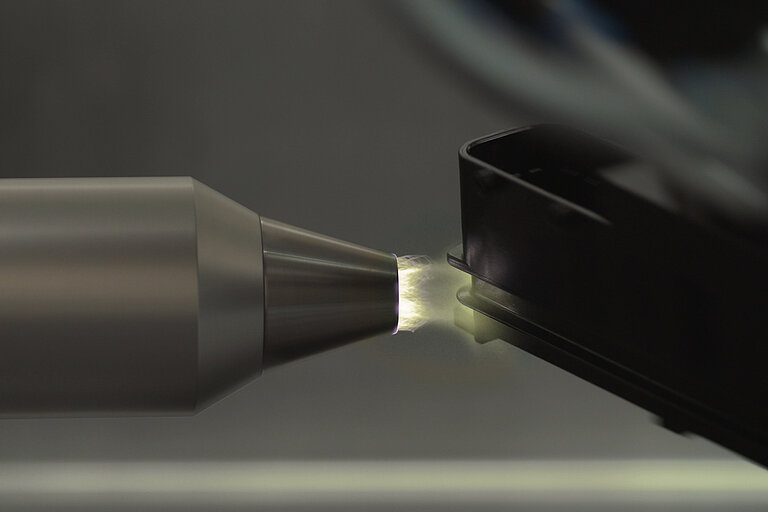

Inline activation using Openair-Plasma® on plastic and metal surfaces for multi-component injection molding technology makes possible firmly bonded composites of plastic-plastic or plastic-metal combinations that in the past could not be bonded at all or were only slightly compatible in bonding.

wfk - Cleaning Technology Institute e.V.

Successful research work in the area of cleaning marks Plasmatreat’s close cooperation with wfk - Cleaning Technology Institute e.V., a German research institute. Graffiti removal with Openair-Plasma® is an alternative to previous methods that is both outstandingly environmentally friendly and saves resources.

Discover the "Graffiti" research project