Car Interior Parts—Plasma for Uniform Surface Activation Over Large Areas

The use of plasma jets on industrial robots allows highly precise, rapid and environmentally responsible surface pretreatment of large three-dimensional car interior parts prior to coating, wrapping, in-mold decoration or in-mold labeling. For pretreatment of parts like instrument panels, door trims or sidewall trims a number of wide-angle rotary plasma jets are used, making it possible to achieve rapid uniform surface activation even over large areas.

Topics on this Page:

Alternative to flame pretreatment Laminating leather to car interior parts Exclusive surface finishes

Alternative to flame pretreatment—Openair-Plasma® pretreatment of exclusive instrument panels without masking

The panel consists of three material layers: a glass-fiber reinforced plastic core, a polyurethane foam layer, and a slush-molded skin (made of PVC or TPU). The core parts are made of injection-molded fiber-reinforced polypropylene. This non-polar plastic needs to be pretreated to make its surface receptive to adhesion processes.With the conventional flame technique, all zones where no foam is to be applied must be masked with thermally stable materials.

Openair-Plasma® technology eliminates this whole work step (masking), because the plasma jet works selectively and with absolute precision. Unlike the flame, it can follow the component geometry with an accuracy in the millimeter range. All that is needed later is to cut slightly into the slush skin along the contours of the untreated zones, and the skin and polyurethane foam behind it will peel off easily.

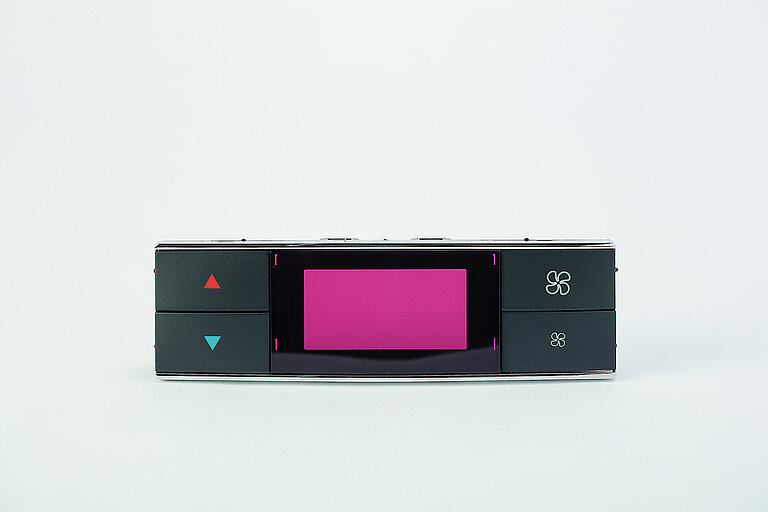

The surface of the plastic core is scanned by industrial robots equipped with RD 1004-type rotary jets that pretreat the entire part in approximately 40 seconds.

Reliable bonding when laminating leather to car interior parts—precise pretreatment of folds

The interiors of luxury automobiles are trimmed with the finest of natural and synthetic leathers. With these exclusive materials, utmost quality and durability are a must – and that can only be achieved by clean and precise processing. One special challenge when applying and laminating such coverings is the folds that have to be made at the edges and corners of parts—when laminating leather to steering wheels, for instance. At these points the material has to adhere instantly and strongly in order to avoid spring-back.

Targeted pretreatment with Openair-Plasma® significantly increases the surface tension of the plastic base material and enables secure bonding – or in other words, immediate and reliable adhesion of the applied polyurethane adhesive.

Interesting success stories in this field

Exclusive surface finishes with low reject rates and high process flexibility

All the surfaces of plastic parts to be installed in car interiors are coated to improve both their feel and their acoustic performance. In car interiors, it is common to find many different painted components—especially in the premium and luxury car segments. Consumers expect these parts to look beautiful over the lifetime of the car while delivering high performance. Meeting these expectations can be difficult for injection molded components made of PC and ABS. These low-cost plastics are coated to achieve a high cosmetic appearance, but the finish can be contaminated by particles adhering to the part surface. In addition, painting around gate marks at the melt delivery points can often reveal flaws caused by internal material stresses. The result is often a high gloss finish such as a pristine piano black coating but with an undesirable "orange peel" effect.

Plasma treatment can effectively reduce both of these phenomena:

- Particle adhesion is reduced by removing organic radicals that are responsible for the adhesion. The component is thus absolutely clean on entering the paint process. The reduction in reject rates as a result of this surface conditioning step can typically reach 20%.

- Mechanical stress, particularly on the part surface are reduced by the heat introduced during the plasma treatment.

Plasmatreat has extensive experience in using both atmospheric Openair-Plasma® and installing the low-pressure Aurora process.

Plasma pretreatment for manufacturing car interior parts with VOC-free coating systems

Furthermore does the automobile industry face the major challenge of drastically reducing VOC emissions from solvent-based materials in car interiors. Consequently, preference is given to coatings based on polyurethane (PU) or to UV coatings. However, these VOC-free coating systems require the substrate to have a high surface tension, which can only be achieved through efficient and uniform pretreatment.

Plasma treatment is a simple and effective way of activating these surfaces. A unit consisting of robots and rotating Openair-Plasma® jets is integrated directly in the production line. The time required for pretreatment with plasma—before coating of steering wheel trim, for example—is less than 10 seconds per part.

Demolding of large-format instrument panels and parts with complex geometries

For manufacturers of large parts with complex geometries made from plastics reinforced with carbon fibers (CRP), glass fibers (GRP), or epoxy and PVC slush-molded skins, easy demolding is an important challenge. Release agents are often applied to facilitate demolding after these parts have been injection molded. Silicone-based mold release agents are the most popular materials applied to the mold surfaces.

However in the manufacturing of class-A finish automotive interior and exterior parts such as door trim, wheel covers, bezels, and instrument panels, a defect free surface is critically important. To ensure the quality of downstream coating processes, it is essential to avoid any carry-over of silicone from mold release agents or the surface can be contaminated and cause rejects.

Low-pressure plasma for long-term coating of molds in injection molding processes.

The Plasmatreat Aurora low-pressure plasma process is especially well suited for depositing durable release coatings on the inside surfaces of molds, making it possible to eliminate silicone-based lubricants and mold release agents. Parts manufactured with plasma deposited coatings exhibit more stable behaviour, with lower reject rates due to contamination and higher part quality.

Coating with the low-pressure method enables optimal downstream processing

The key to this improvement is that plasma generated by this low-pressure technique is able to easily penetrate even the narrowest gaps, no matter how complex the part geometry. The release coating is compatible with a wide variety of mold surfaces, and is engineered to last for thousands of molding cycles. This allows parts to be painted, without any additional pre-treatment steps.

This low-pressure plasma mold release process is already being successfully used aircraft manufacturing and offers great potential for vehicle manufacturing.