Openair-Plasma® allows for fully automated cleanroom painting

Modern touchscreens, LCD displays and TV screens make high demands on production processes as the plastic parts must be provided with highly transparent scratch-proof and anti-static coatings before they are bonded. The high degree of automation in the electronics industry demands a surface treatment process that can perform inline with the utmost reliability, delivering a high degree of activation at high speed.

Crystal-clear displays: plasma treatment for flawless protection and functional coatings

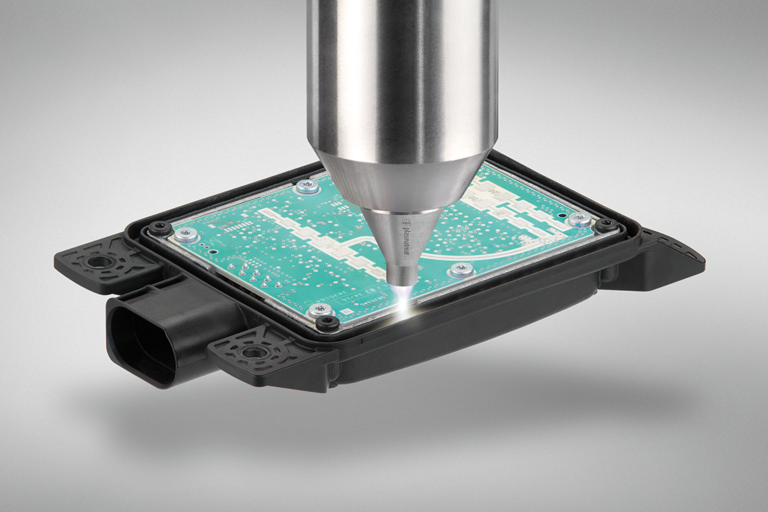

The microfine atmospheric plasma cleaning and plasma activation provided by the Openair-Plasma® process offers the electronics industry extremely effective solutions. Plastic displays are treated with plasma directly before application of the antistatic and scratchproof coating in the coater. Thanks to the high surface energy achieved by the Openair-Plasma® technology, the applied coating spreads evenly to form a homogeneous film. This results in a flawless appearance and significantly reduces reject rates in production.

Openair-Plasma® treatment offers many persuasive advantages to electronic manufacturing and assembly:

- Suitable for both selective and large-area surface pretreatment;

- Higher quality coating and higher quality adhesion with lower error rates;

- Outstanding control of physical process compared to wet chemical processes;

- Significant simplification of your process chain; and

- Ecologically responsible because it produces no waste products.

Significantly less scrap when Openair-Plasma® micro-cleaning is used prior to anti-static coating of TV screens

The Openair-Plasma® process has been used for years by leading manufacturers to improve the quality of their anti-static coating on cathode ray tubes. Now the same quality is available in the manufacture of LCD and LED monitors.

Even the smallest particle of dust embedded during coating can mean an entire component must be scrapped. Even when a cleanroom is used, integrating micro-cleaning with Openair-Plasma® results in additional, significant reduction in scrap rates.

Glass-clear appearance, scratch-proof surfaces – Openair-Plasma® treatment for plastic and LCD displays

Displays are coated with a special coating during the last stage of the manufacturing process. This coating improves scratch resistance and enhances the quality of surfaces such as those made of PC (polycarbonates) and PMMA (polymethyl methacrylate).

To ensure that this coating adheres, surfaces must be pretreated. Openair-Plasma® offers the perfect inline process to accomplish that, replacing elaborate processing that uses low-pressure plasma treatment.

This means a significant simplification of the process chain in the manufacture of displays and a substantial reduction in scrap rates.

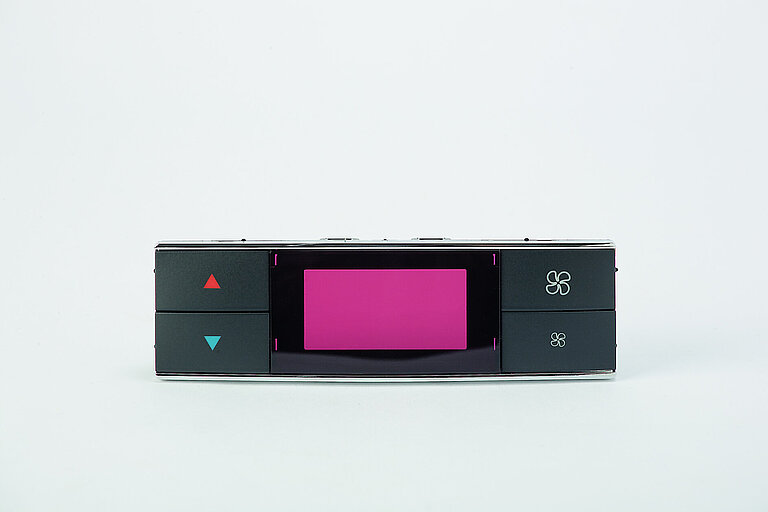

Plasma cleaning ensures strong bonding of LCD displays

Displays for digital gauges and indicators, radios, on-board computers, mobile telephones, and laptop monitors are bonded with a flexible film or conductive rubber, using a hot sealing process. The film forms a flexible connection between the circuit board and the contact surface that generally comprises two thin panes of glass.

The simple principle used in Openair-Plasma® pre-treatment removes every trace of carbohydrates and impurities from these contact surfaces. This results in a uniformly high bonding quality and a reduction of scrap rates. The same applies to this process with hot bar soldering and micro-welding.

High expectations: unbreakable and scratch-proof display surfaces

The requirements for displays in modern smartphones and tablets include thin, lightweight materials that look good and are resistant to harsh handling. These handheld displays use the toughest glass available (e.g., gorilla glass). Although this glass offers extremely high scratch resistance, it is still vulnerable to breakage. Therefore, displays that must be both unbreakable and lightweight are made of polycarbonate.

Scratch-proof smartphone displays made of polycarbonate

Thanks to a Plasmatreat surface coating applied with a low-pressure plasma method, polycarbonate can now be used to manufacture displays for hand-held devices like cell phones and tablets. Without treatment this material is susceptible to scratching, but after depositing a plasma coating inside the chamber, it is transformed into an ultra-hard surface that is virtually scratch-proof.

Our news about display manufacturing

Our next PlasmaTalks and Events

High-quality consumer cameras thanks to coordinated Openair-Plasma® surface treatment and special adhesives

Upcoming Exhibitions and Events

Get to know Plasma up close at our trade fairs and events!

NPE 2024

West Building Level 2 - Expo Hall, Booth W7479

Orange County Convention Center

Orlando, Florida

SMTconnect

Hall 4, booth 351

NürnbergMesse

Karl-Schönleben-Str.

Messeplatz 1

90471 Nuremberg

Germany

Advanced Engineering 2024

Booth P154

NEC Birmingham

North Ave, Marston Green

Birmingham