Openair-Plasma® in Vehicle Construction: bicycles / motorcycles

Fiber-reinforced plastics are the main materials used in the manufacture of painted parts (such as cladding, tanks, fenders, etc.) In conventional processes, they are power washed and then flame-treated, followed by primering.

Using Openair-Plasma® significantly reduces the number of process steps. Precleaning is no longer required, and plasma pretreatment replaces flame treatment, and greater activation of surface tension is achieved without attacking the fiber structure. This means primer does not have to be applied either.

The result is a particularly stable paint adhesion and even color finish. It has also been proven that pretreatment with Openair-Plasma® significantly increases resistance to stone pitting on painted components.

Process optimization for primerless painting in motorcycle manufacture: Openair-Plasma® for optimal paint adhesion and cool designs!

Interesting success stories in this field

High-tech for bicycle racing, environmentally responsible production: carbon-fiber composites removed from molds without use of release agents

Use of carbon-fiber composites makes high-performance bicycles extremely light and strong. To reduce wind resistance, shapes must be designed to be absolutely aerodynamic. Bicycle frames are manufactured in a multi-layering process and then thermally cured in an autoclave.

Release agents are required to then remove these complex individual parts from the molds. Residues of these release agents remain on the surface after demolding and then must be removed in an elaborate process.

Openair-Plasma® combined with PlasmaPlus® is used to replace these release agents with a plasma polymer nano-coating that securely adheres to the mold. This means that no unwanted release agent remains on the surface when parts are removed from the mold.

In a subsequent step, the finished frames are completely scanned using a robot system and optimally prepared with RD1004 rotating plasma jets for the painting that follows. This also means that environmentally responsible, water-based paint systems can be used without any difficulty.

Longer life with greater engine output: Openair-Plasma® cleaning for high performance two-stroke engines

Working together with a leading German university in the field of engine development, Plasmatreat has developed a process that significantly increases the heat dissipation from the interior hard coating in the cylinder barrel to the air-cooled engine block.

Micro-cleaning and surface augmentation with Openair-Plasma® significantly improves the bonding of the coating, combined with reliable heat transfer. This simultaneously extends engine life and increases the potential for improved engine performance. The hard coating is then applied in a plasma spraying process.

Unique shapes make motorcycle headlights attractive – Openair-Plasma® supplies absolutely impermeable long-term adhesion.

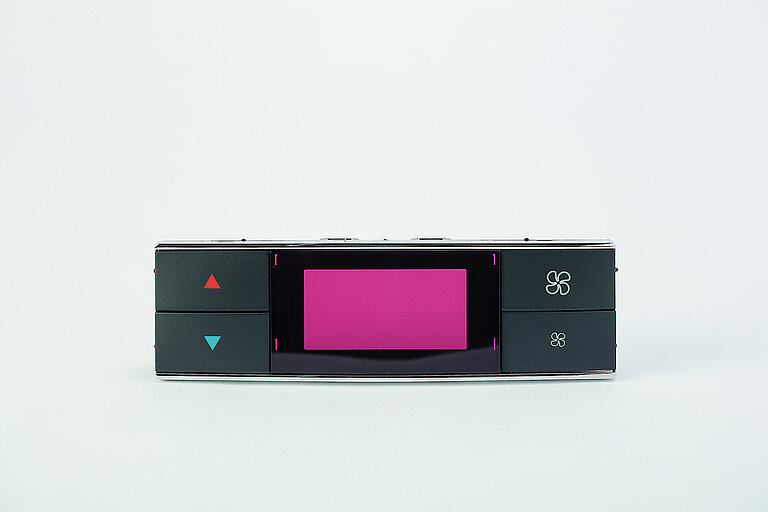

Headlights are constructed basically from a casing, a reflector and plastic end cap. The demands of up-to-date and multifaceted designs often mean that space for glue joints is greatly restricted. The space remaining requires a secure bond that is impenetrable to water vapor.

With Openair-Plasma® it is possible to combine a variety of plastic materials, such as polypropylene and polycarbonate. Plasma activation results in precisely targeted increase in surface tension along with micro-cleaning of area where the glue is to be applied. All common types of adhesives are suitable for the subsequent bonding operations, such as silicone, polyurethane rubber and especially single-component warm melt adhesives with high initial strength.

The ease of integrating Openair-Plasma® technology in inline processes results in highly efficient process designs as well.