Openair-Plasma® systems for the inline pretreatment of profiles made of plastic, aluminum or EPDM

Openair-Plasma® technology is a leading process for the surface treatment of profiles and molded parts made from materials such as plastic, aluminum or EPDM. Particularly in the automotive industry, it has become indispensable after only a short time in use. In the furniture industry also, Openair-Plasma® ensures high process efficiency, for example for profile wrapping.

Plasma profile treatment during extrusion prepares plastics and elastomers for subsequent coating, wrapping, flocking, application of tapes, or two-component extrusion. The Openair-Plasma® process is used to cleanand activate the substrate material. The targeted, concentrated plasma jet, movable jet heads, and inline integration on robot arms makes it easy to pretreat even complex profiles.

Openair-Plasma® treatment systems are usually equipped with 4, 8, 12, or 16 plasma jets and can easily be integrated into an existing production line.

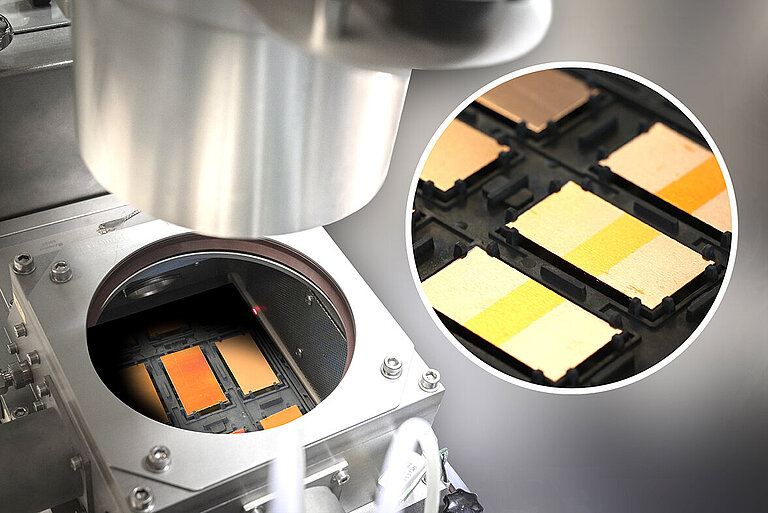

A large number of plasma jets is integrated in a very small space in the EPDM plasma treatment system. The system is easy to clean, can be operated comfortably on both sides, can be opened wide due to the hinged cover and is thus easily adjustable. The system is designed for a dusty work environment and fluctuating temperatures.

The digital generator technology (FG500x Series) makes possible energy-efficient pretreatment, easy operation, and full system integration.

FEATURES &

ADVANTAGES

Openair-Plasma® systems

in EPDM extrusion

- Cost-efficient inline integration

- Measurable reduction of scrap rates

- Reliable process monitoring with the plasma control system

- Robust system technology with > 99.5% availability

- Simple, reproducible arrangement of the plasma jets to the profile

- Short setup times

Plasmatreat special systems for profile treatment in the furniture industry

Openair-Plasma® makes possible the effective pretreatment of furniture and window profiles. The plasma system is integrated inline directly in the wrapping process just ahead of the film pressing station. This plasma treatment allows the reliable use of solvent-free adhesives on the otherwise non-polar profile surfaces. The additional application of primers is not necessary.

Different rotary jets are used for this application. Jointly with its customers, Plasmatreat is always developing new solutions for plasma treatment both for the furniture industry and other industrial applications. The advantage of Openair-Plasma® in profile wrapping is in particular the reliable, continuous process flow and the simple, reproducible process.

You want to test our products for your material?

Give it a try: Our experienced application engineers are looking forward working with you to find the best solution for your use case. In our well-equipped laboratories, together we will pretreat your individual parts with our plasma technology and analyse the results.