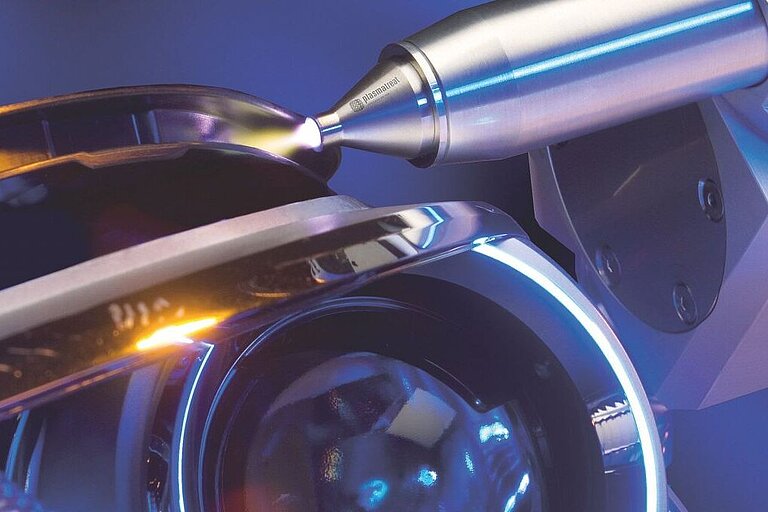

PlasmaPlus®: selective plasma coating in all different types of application

All different types of materials like plastic, glass, metal, aluminum, PET film, textiles, etc. can be coated with PlasmaPlus®. Plasma polymerization with the PlasmaPlus® process is already being used successfully for surface coating in a large number of different industrial applications.

PlasmaPlus®: nanocoating for an increased effect

The effect of plasma can be increased even further. With the aid of PlasmaPlus® technology developed by Plasmatreat, selective nanocoatings are applied to surfaces that can be superhydrophobic and superhydrophilic, for example.

This can be used to coat different materials such as plastic, glass, ceramics, metal, aluminum, PET film, textiles, etc. and create functionalized surfaces.

These improve, for example, the barrier properties, enable long-term stable bonding or coating, serve as a demolding layer in injection molding, provide corrosion protection or effectively support the reliable bonding of hybrid components.

In the PlasmaPlus® process, the plasma beam is additionally injected with a gaseous precursor tailored to the application in question, which can be used to produce an ultra-thin plasma layer to achieve the desired surface properties.

Plasma polymerization with Plasmatreat's PlasmaPlus® process is already being used successfully in a wide range of different industrial applications for surface coating.

How the PlasmaPlus® technology works:

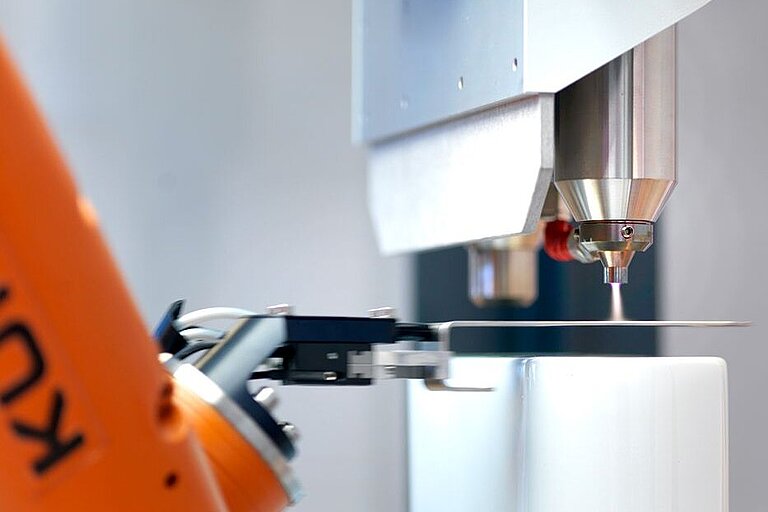

An Openair-Plasma® system is equipped with the PlasmaPlus® system. This system allows the vaporization of an additive that is liquid at room temperature, which can be introduced into the plasma using a carrier gas in a precisely reproducible manner. Hydrophilic, and for the first time also hydrophobic, nanocoatings are produced with specific coating thicknesses up to 1000 nm (nanometers). All different types of materials like plastic, glass, metal, aluminum, PET film, textiles, etc. can be coated with PlasmaPlus®. Plasma polymerization with the PlasmaPlus® process is already being used successfully for surface coating in a large number of different industrial applications.

By this innovative technology we have been enabled to make totally new applications accessible.

Examples of successful PlasmaPlus® applications:

- Improvement of barrier characteristics of plastics for packaging using plasma polymer nanocoating

- Paintability with long-term stability and resulting high flexibility in manufacturing thanks to nanocoating with PlasmaPlus®

- PT Release coatings, for injection molding tools, allow a high number of process cycles without the components having to be stressed with release agents that contain silicone.

- PT Bond coatings assure long-term adhesion in the adhesive joint

- Because of their good barrier effect, the AntiCorr® corrosion protection coatings with PlasmaPlus® offer extremely high corrosion protection with long term resistance to corrosive electrolytes – especially for aluminum alloys

- Plasma-SealTight® realizes particularly strong adhesion and corrosion-resistant metal-plastic hybrid components in the injection molding process

PlasmaPlus® nanocoatings on surfaces

Using a special nozzle head, specific additives are supplied to the plasma depending on the application. These are excited by the plasma, which significantly increases their reactivity. This allows the substances to optimally accumulate on the material surface and bond tightly. A coating develops with functional surface characteristics that can be adjusted individually to the process. With PlasmaPlus® technology, different materials like metals, glass, ceramic and plastics.

For this purpose, an Openair-Plasma® system is equipped with the PlasmaPlus® system. This system allows the vaporization of an additive that is liquid at room temperature, which can be introduced into the plasma using a carrier gas in a precisely reproducible manner. Hydrophilic, and for the first time also hydrophobic, nanocoatings are produced with specific coating thicknesses up to 1000 nm (nanometers).

FEATURES &

ADVANTAGES

Successful PlasmaPlus® applications:

- Improvement of barrier characteristics of plastics for packaging using plasma polymer nanocoating

- Paintability with long-term stability and resulting high flexibility in manufacturing thanks to nanocoating with PlasmaPlus®

- PT-Release coatings, for injection molding tools, allow a high number of process cycles without the components having to be stressed with release agents that contain silicone.

- PT-Bond coatings assure long-term adhesion in the adhesive joint.

- Because of their good barrier effect, corrosion protection coatings with PlasmaPlus® offer extremely high corrosion protection with long term resistance to corrosive electrolytes – especially for aluminum alloys.

- Plasma-SealTight® realizes particularly strong adhesion and corrosion-resistant metal-plastic hybrid components in the injection molding process.