Solutions for various industries

We think in surfaces. As the world's leading manufacturer of plasma units and systems, Plasmatreat develops solutions for the pretreatment of surfaces. Applications focus on the industrial-scale microfine cleaning, activation and coating of surfaces made from materials such as plastics, metals, glass, cardboard, textiles and composites – materials that are used in virtually all sectors of manufacturing industry.

From automotive engineering, transportation, electronics and packaging to consumer goods, life sciences, textiles and renewable energies – we provide cross-sector advice and support to customers. Thanks to the very diverse range of applications for Openair and Aurora plasma technology, we develop new, highly efficient process solutions on a virtual daily basis – individually tailored to the needs of our customers.

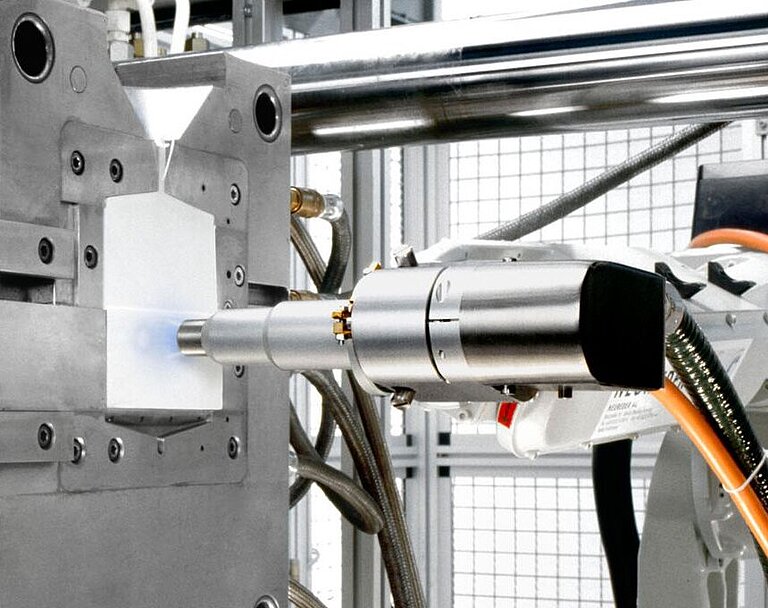

Openair-Plasma® treatment is used in almost all industrial manufacturing processes

Automotive Engineering

The automotive industry relies on robust, finely tuned processes. These are basic preconditions for achieving consistently high quality. At the same time, durable adhesive bonds and the use of advanced materials are major production parameters when manufacturing parts with complex shapes. Openair-Plasma® treatment meets the tough requirements of the automotive industry like no other pretreatment technology and is therefore firmly established in a variety of production processes at leading manufacturers.

Electronics

In the electronics industry, Plasma pretreatment is a key asset for achieving cost-effectiveness and process reliability. For transparent, scratch-proof coating of displays, it significantly reduces the reject rate and ensures a flawless appearance. When printing electrically conductive coatings on printed circuit boards, prior plasma activation, microfine cleaning and electrostatic discharge ensure that the coating will adhere securely. In chip packaging, Openair-Plasma® microfine cleaning eliminates the need for a vacuum chamber.

Consumer Goods

Consumers are expecting more and more from the products they buy: flawless printing and coating on high-gloss surfaces, durable adhesive bonds, furniture edges with zero bondlines, pollutant-free production, new innovative material combinations, surfaces with dirt-repellent, non-stick, sterilizing or flame-retardant functional coatings – to name but a few examples. Openair-Plasma® and PlasmaPlus® pave the way for innovative and cost-effective solutions in many different application areas.

Packaging

Plasma pretreatment has proved to be an especially efficient method in the packaging industry. In extruding plastic films, printing and bonding of non-polar materials such as polypropylene, polyethylene and recycled materials, Openair-Plasma® is a key technology for cost-effective and environmentally responsible manufacturing. PlasmaPlus® nano-coating also helps to create new barrier properties for food packages.

Life Sciences

Sterilizing microcleaning with Openair-Plasma®, facilitating new material combinations for implants, functional coating of instruments, clothing and equipment, pretreatment of microfluidics or balloon catheters with Aurora Plasma – all of these open up new options in medical technology and the life sciences.

Transportation

Transport is an industry where Plasma can display the full breadth of its application possibilities. In aircraft and aerospace manufacturing, atmospheric plasma pretreatment enables the use of completely new material combinations. In shipbuilding, pretreatment can take place directly in the shipyard thanks to Openair-Plasma® technology. Truck and trailer superstructures gain extra structural integrity and durability thanks to plasma activation of substrates before bonding. And the integration of Openair-Plasma® in two-wheeler manufacturing can eliminate entire production steps.

Transportation

Textile Manufacturing

Openair-Plasma® pretreatment significantly improves the wettability of fibers and yarns, allowing even solvent-free dyes to bond well and durably. Surfaces can be provided with hydrophobic and dirt-repellent finishes. Openair-Plasma® jets can keep pace with the tough demands of new high-performance spinning equipment. Aurora Plasma pre-treatment significantly improves the wettability and thus the bonding of reinforcing fabrics.

Renewable Energies

New environmental consciousness is a central issues of our time. The goals are:

- Increasing performance and reducing production costs per kWh of renewable energy technologies

- Storage of energy in high-efficiency gas accumulators and battery systems

- Energy-saving construction and effective insulation in home and industrial construction

- New, more efficient processes in all areas of industrial production