Plasma systems for light-weight panels

In many industries, such as vehicle manufacturing and the furniture industry, light-weight construction holds a great deal of promise in meeting critical challenges of the future. Light-weight panels, for instance, can reduce raw materials costs, increase the efficient use of energy in production operation, and reduce logistics costs.

A number of layers must be successfully bonded to each other in the production of light-weight panels. The core of a light-weight sandwich panel is a honeycomb-structured board made of polypropylene reinforced with glass fibers, which reduces its weight and gives the panel a high degree of stiffness. -The board is then given a high-quality paint finish.

Plasma treatment for PP honeycomb panels

A number of layers must be successfully bonded to each other in the production of light-weight panels. The core of a light-weight sandwich panel is a honeycomb-structured board made of polypropylene reinforced with glass fibers, which reduces its weight and gives the panel a high degree of stiffness. The board is then given a high-quality paint finish.

Reliable bonding and cost-efficient production

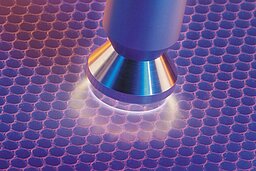

Wide-area pretreatment at a high speed is an absolute must for reliable bonding of the composite elements and paint on nonpolar materials.

The Openair-Plasma® inline plasma system opened up the possibility of cost-effectively manufacturing composite panels. The Plasmatreat XRD1010 plasma treatment systems with multiple rotary jets combine high-performance activation with wide path treatment and the greatest treatment speeds. With Openair-Plasma® treatment, alternative materials such as recycled plastics and wood-plastic composites (WPC) can be used with confidence as well.

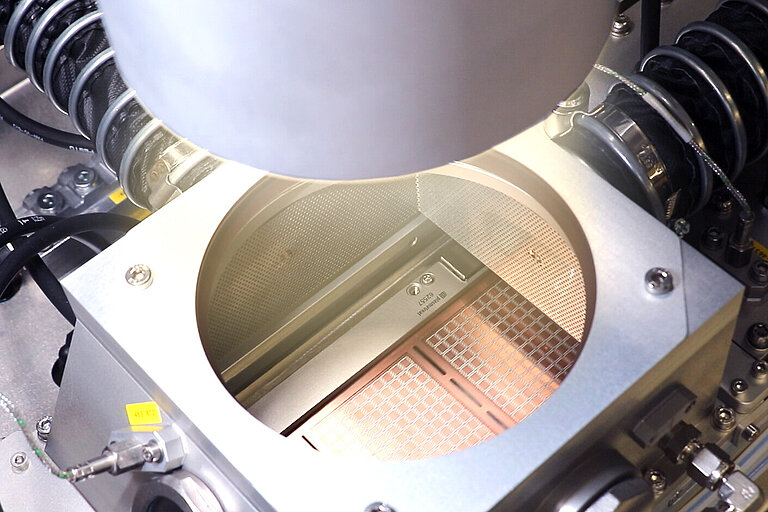

The plasma large panel system comprises three main elements: the generators (left), the panel pretreatment system (center) and a height-adjustable maintenance platform (right).

The plasma rotary jet equipment from Plasmatreat can pretreat sandwich panels up to 3 meters wide at speeds of up to 25 m/min in continuous inline production.

You want to test our products for your material?

Give it a try: Our experienced application engineers are looking forward working with you to find the best solution for your use case. In our well-equipped laboratories, together we will pretreat your individual parts with our plasma technology and analyse the results.