Windshields – VOC-free bonding of glass

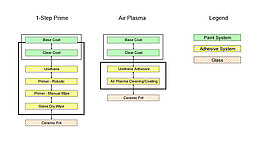

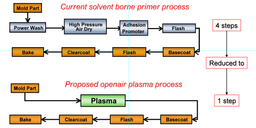

When installing windshields in automotive manufacturing, the ceramic-coated edges of the glass panes have to be bonded with a painted flange area of the metal body. To achieve the necessary adhesion, it has been imperative until now to treat such ceramic-coated glass surfaces with chemical primers. These primers contain easily volatile solvents that are released into the environment during production and, to some degree, also later in the car itself.

Ford Motor Company has succeeded for the first time in replacing this entire wet-chemical pretreatment with an environmentally friendly, VOC-free and fully automated process plasma polymer nano-coating with the PlasmaPlus® process is an excellent application in the area of adhesive technology.

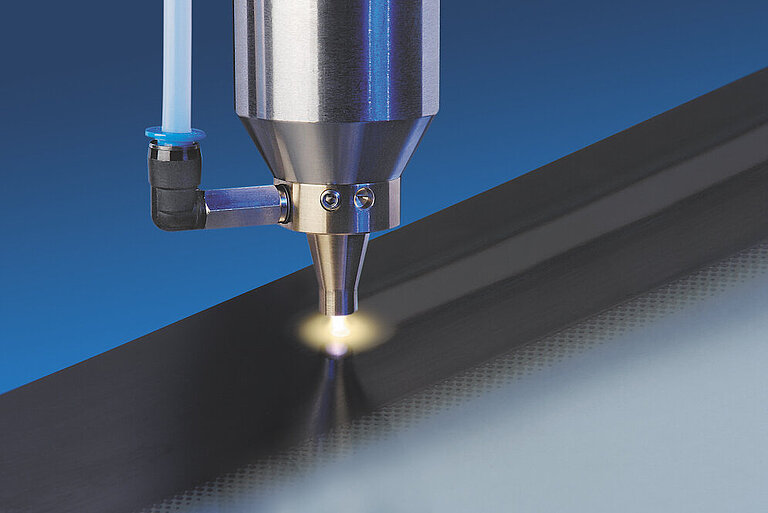

First, Openair-Plasma® cleaning provides a micro-fine cleaning and, at the same time, high surface activation of the ceramic coating. The PlasmaPlus® nano-coating selectively applied immediately following the cleaning ensures reliable adhesion of polyurethane (PU) adhesives to the glass-ceramic surface of the windshield.

Environmentally friendly, no VOCs: primer-free bonding of windshields with Openair-Plasma® coating

ADVANTAGES OF

PLASMA TREATMENT

of windshields with

Openair-Plasma® and PlasmaPlus®

- Reliable ultrafine cleaning with simultaneous high uniform surface activation

- Complete elimination of solvents containing VOC

- Reliable adhesion of glass-ceramic surfaces and metal

- High process availability, full process automation, easy inline integration

- Reduction of material and operating costs

- Environmentally friendly and cost-efficient

The new patented process has the potential to reduce costs.

Interesting success stories in this field

Plasma Treatment for bonding of glass-ceramic surfaces

Primers eliminated thanks to Openair-Plasma® treatment for bonding of glass-ceramic surfaces.

Windshield Bonding. Plasma treatment and nano-coating of windshields

Shorten the production process for windshield bonding with Openair-Plasma® treatment and PlasmaPlus® nano-coating.