Measuring surface energy – The starting point for plasma pretreatment

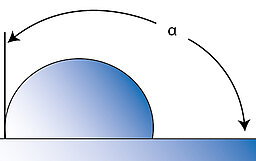

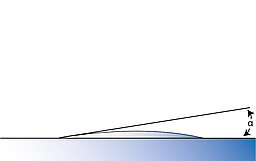

Every material surface has a specific surface energy. Every liquid (such as ink) also has an inherent tension. Reliable adhesion with long-term stability of printing, gluing or coating requires that the surface energy of the material is greater than that of the liquid. Plastics, for example, have predominantly low surface energy (often less than 28 mN/m). If these plastics are to be printed, a surface energy of 40 mN/m for solvent inks or a surface energy of 56 mN/m for UV-curing systems is required. If water-based paint systems are used, the surface energy has to be above 72 mN/m.

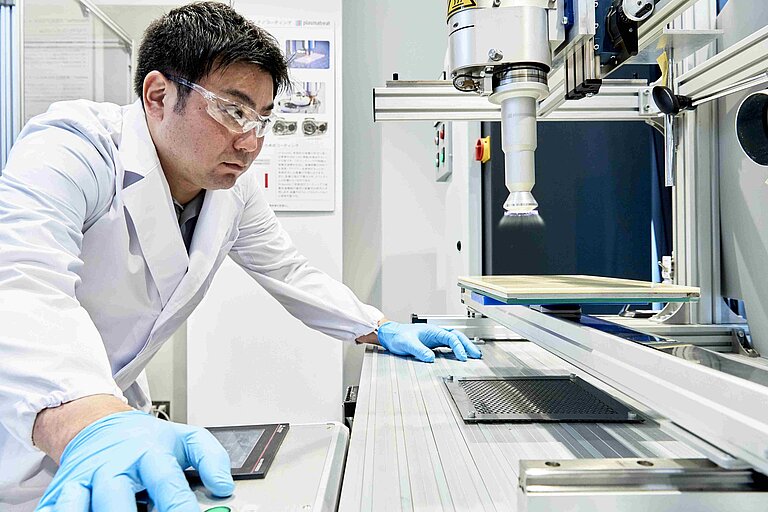

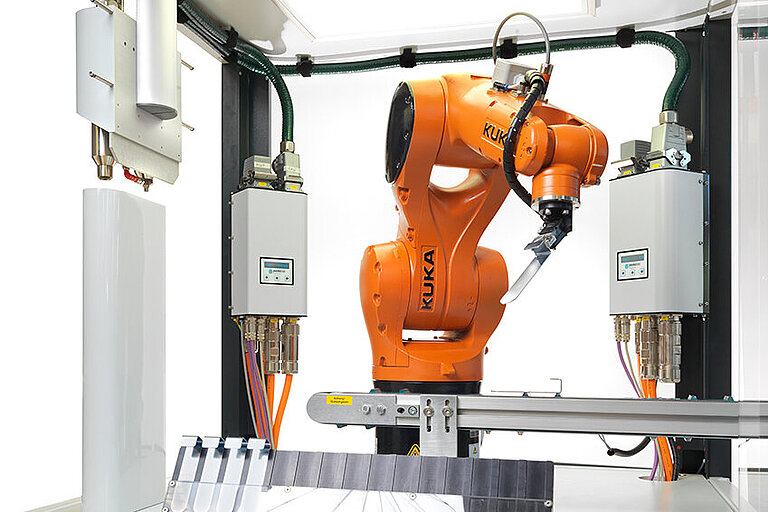

For many industrial applications it is crucial that adhesives and/or printing inks and surface properties are optimally aligned. Targeted pretreatment with atmospheric-pressure plasma achieves a significant increase in surface tension. This gives materials the optimum capabilities for accepting printing ink (wettability) or adhesion.

Comparison surface energy - before and after plasma treatment